Into the Lab

CIVIL Faculty member Anton Schindler and graduate student Benjamin Byard, left, are researching the effect of lightweight aggregates (LWA) and curing temperature on the cracking tendency of bridge deck concrete. Cracking of concrete occurs when the induced tensile stress exceeds the tensile strength of the concrete. The strength of concrete is impacted by concrete composition, the properties of its ingredients, the curing method and the temperature history that the concrete experiences. The development of in-place stresses is affected by shrinkage, stiffness, the coefficient of thermal expansions, the application and restraint conditions, the stress relaxation and the temperature history of the concrete. Because the properties of concrete are always changing due to the hydration of the cementing system, it can be difficult to capture their combined effect. Rigid cracking frame testing techniques use instrumented frames that restrain concrete samples from shrinking. The stress in the concrete that is measured is due to the net behavior of all of the aforementioned effects. This research evaluates the effect of LWA and placement temperature using rigid cracking frame testing techniques. Using concrete temperature modeling software, the temperature history of a given concrete mixture can be modeled for a specific application, place and time of year. Software was used to develop a temperature profile of a bridge deck construction in Montgomery for summer and fall conditions. The concrete samples were tested under constant temperature curing condition and were match-cured to the bridge deck temperature profile. The use of LWA was found to be effective in reducing the stress in the concrete, which should improve the performance of bridge decks placed with this concrete type. AEROSPACE

Tornados are lethal whirling masses of air that evoke fear because of their destructive power. In the atmosphere, tornados are created by a combination of pressure fronts, humidity, temperature differences and the Earth’s rotation. The scientific term for a tornado is a “line vortex” or simply “vortex.” These vortices are often encountered in the wake of airplanes and are sometimes visible as contrails. At busy airports, these vortices can pose a serious hazard for planes landing in rapid succession. The Federal Aviation Administration therefore requires large separation distance between landing aircraft to minimize wake induced turbulence, which results in an increase in time between landings and loss of landing fee revenue to the airports. A number of research efforts have focused on destroying these tornado-like vortices. In the Department of Aerospace Engineering, one such project is creating a vortex that originates from the tip of an airplane wing and then weakens. BIOSYSTEMS

Auburn’s Center for Bioenergy and Bioproducts will lead the project and work with faculty in the Department of Biosystems Engineering and the School of Forestry and Wildlife Sciences. Other collaborators include the U.S. Department of Agriculture Forest Service, as well as companies from across the U.S. and Canada, including Corley Land Services, TigerCat, Barnes Enterprises, Blue Ox Forestry and Dixie Pellet. The production process involves harvesting pine trees, allowing them to partially dry, chipping them and transporting the material to a biorefinery to process it into cellulosic biofuels. Specific project objectives are to improve the design of tree-length harvesting machines to increase productivity and minimize their environmental impacts; assemble a high-productivity, lowest-cost harvesting and transportation system for biomass; and demonstrate and document the performance of this system at an industrial scale. CHEMICAL As part of a joint venture agreement between Auburn University and the U.S. Department of Agriculture’s Forest Service Forest Products Laboratory, faculty members Harry Cullinan and Gopal Krishnagopalan have developed a selective and efficient pre-extraction and modified pulping process for softwood that maintains yield and pulp quality. A large fraction of hemicelluloses in wood chips is dissolved into black liquor during the pulping process. This portion is basically wasted, as only its fuel value is recovered. Integrating biorefineries with existing forest based industries would allow for significant economic growth through new value-added products and higher resource utilization. Recovery of the hemicelluloses was achieved by prehydrolyzing the wood chips using hot water, steam or acid to remove the hemicelluloses before the actual pulping process. The major effect that needed to be researched was the quality of the pulp and paper products produced from prehydrolyzed wood chips. The process will now be scaled up for testing in a lab digester. This will involve additional work to screen less expensive additives for pretreatment and optimize pretreatment and cooking conditions. COMPUTER SCIENCE AND SOFTWARE Faculty member N. Hari Narayanan is collaborating with colleagues at Washington State University and University of Hawaii to study a way of teaching computing concepts to undergraduates called studio-based learning (SBL). The project is supported by a two-year grant to the three universities from the National Science Foundation (NSF) totaling almost $550,000. Studio-based instruction is adapted from design-oriented disciplines, such as architecture, and is aimed at empowering students to learn collaboratively. At Auburn, Narayanan worked with Margaret Ross in educational foundations, leadership and technology, and Dean Hendrix in computer science and software engineering, to test the efficacy of SBL in undergraduate courses over the past two years. Preliminary analyses of data collected from these courses indicate that not only do students learn more, but also that their sense of community, self-regulation, motivation and critical thinking skills increases significantly. Encouraged by results, the investigators have submitted a proposal to the NSF to support the implementation and evaluation of SBL on a national scale. They have secured participation of faculty from 15 colleges and universities in 10 states and are awaiting NSF review of their proposal. ELECTRICAL AND COMPUTER The Department of Electrical and Computer Engineering and the Wireless Engineering Research and Education Center recently participated in the Jules Collins Smith Museum’s Sixth Birthday Bash. Faculty member Thad Roppel and students from the department hosted an activity table where kids could build crystal radios and use them to listen to Elvis’ music from a low-power AM transmitter. Eight electrical and computer engineering student volunteers helped dozens of children do just that, making the activity, “10-minute radio,” the hit of the show. The team was equipped to build five radios at a time, and the activity table remained full throughout the three-hour event. Many of the participants were younger children, with both boys and girls showing interest in building a radio. The activity had a large impact on the kids, as seen from the expressions on their faces when they heard Elvis’ music through their earphones. ECE student volunteers did an outstanding job, working with even the youngest children, and it was obvious that the parents were just as thrilled as the kids. With the success of this event, the department plans to use the 10-minute radio project for future recruiting and outreach events, such as E-Day and elementary school classroom and extracurricular programs. INDUSTRIAL AND SYSTEMS

Gue’s research interests include logistics modeling and optimization, warehousing, distribution and material handling. Edwards’ areas of expertise include personnel recruitment, selection and training, group dynamics and organizational change and development. Gue is the immediate past president of the College-Industry Council on Material Handling Education. MECHANICAL Faculty member Sushil Bhavnani was recently awarded grants from the National Science Foundation Chemical, Biological, Environmental and Thermal Systems Directorate, and the NASA Headquarters Exploration Systems Mission Directorate to support his research efforts in electronics packaging. This project will focus on boiling mechanisms during thermally-actuated pumping using asymmetric microscopic surface structures. This is a collaborative research and educational program between investigators at Oregon State University and Auburn in the general area of phase-change heat transfer enhancement. The goal is to characterize the effect of a passively imposed asymmetric force on a bubble during the boiling process. Such asymmetry is created by the use of a surface with repeated ratchet structures and pyramidal re-entrant cavities located on one of its sides. The hypothesis is that with several ratchets, this local asymmetric motion can be translated to a net fluid pumping. This will enable the efficient dissipation of heat from microelectronic components. As part of the funding agreement, educational activities will provide a synergy between research and education, as well as between several universities. POLYMER AND FIBER

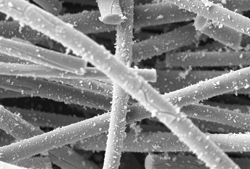

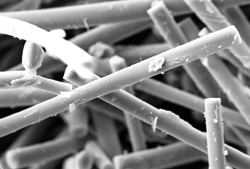

Fuel cells are the most promising alternative energy sources for transportation vehicles and electronic devices. However, they are prone to poisoning with certain chemicals in contaminated areas even more than human lungs. This becomes especially critical for the operation of fuel cell powered vehicles and electronics in battlefield conditions. In a proton exchange membrane fuel cell (PEMFC), ambient air rather than pure oxygen is the most economical way to feed the cathode. However, impurities in air, such as sodium dioxide (SO2), may contaminate a fuel cell, resulting in membrane electrode assembly damage and performance degradation by occupying reactive sites on catalysts. The severity of the effects of these impurities varies. Using a wet laying process, faculty member Sabit Adanur and graduate student Wei Liu are developing activated carbon fiber (ACF) filters for fuel cell cathodes to absorb contaminants from the air and reduce or eliminate fuel cell poisoning. Through their research, the team has found that potassium permanganate (KMnO4) modified fibers are suitable for the wet-laying method to fabricate ACF filter media without losing SO2 capacity. |

|||||||||||

|

Engineering E-Mag is a service of the Samuel Ginn College of Engineering. This newsletter is distributed to alumni and friends throughout the year. To read archived copies visit: http://www.eng.auburn.edu/. To learn more about the Samuel Ginn College of Engineering, visit our Web site at:http://www.eng.auburn.edu/. QUESTIONS about Engineering E-Mag may be directed to Michael Stone, Webmaster for the Samuel Ginn College of Engineering, at webmaster@eng.auburn.edu Auburn University is an equal opportunity educational institution/employer. |

|||||||||||

The Department of Energy (DOE) has awarded Auburn researchers a $4.9 million grant to develop new production systems that collect woody biomass for making bioenergy. Auburn faculty will work with equipment designers on machine improvements and will develop and implement new sensors and GPS-based systems to help improve the performance of forest-harvesting machines and the quality of the final biomass product. One of five DOE projects for biomass logistics research, it is the only project targeted at southern forests.

The Department of Energy (DOE) has awarded Auburn researchers a $4.9 million grant to develop new production systems that collect woody biomass for making bioenergy. Auburn faculty will work with equipment designers on machine improvements and will develop and implement new sensors and GPS-based systems to help improve the performance of forest-harvesting machines and the quality of the final biomass product. One of five DOE projects for biomass logistics research, it is the only project targeted at southern forests.

Faculty member Kevin Gue, left, and Oklahoma State University colleague Bryan Edwards were recently awarded a $54,000 grant to initiate a broad-based study of the material handling industry by the Material Handling Industry of America and the College-Industry Council on Material Handling Education. The primary objectives of the grant are to examine factors that affect turnover, satisfaction, commitment and performance, as well as acceptance or resistance to technology adoption. The grant will fund two graduate students for one year. This work is part of a large-scale effort to understand worker-centric design in the context of distribution centers.

Faculty member Kevin Gue, left, and Oklahoma State University colleague Bryan Edwards were recently awarded a $54,000 grant to initiate a broad-based study of the material handling industry by the Material Handling Industry of America and the College-Industry Council on Material Handling Education. The primary objectives of the grant are to examine factors that affect turnover, satisfaction, commitment and performance, as well as acceptance or resistance to technology adoption. The grant will fund two graduate students for one year. This work is part of a large-scale effort to understand worker-centric design in the context of distribution centers.